Technology

WET Systems specialize in the development of tailor-made, sustainable solutions to your water quality challenges, with ecologically engineered, nature-based and constructed wetland technologies at the core.

Wetland and Ecological Treatment Systems take advantage of the natural contaminant transformations, energy flows and material balances that occur in wetlands and other aquatic ecosystems, only in a more optimized and engineered way, in order to remove pollutants from water.

By working with Mother Nature (rather than against her), wastewater treatment processes can be engineered to operate with significantly lower use of fossil fuels, chemicals and mechanical equipment compared to conventional technologies. This translates to significant savings in operation and maintenance costs over the life of a system. These benefits often come at the cost of a bigger land area requirement; although through clever design, compact ecological systems are also possible, so it is always worth enquiring before ruling out a more sustainable solution.

With the primary goal of developing the most sustainable, reliable and robust solution for each project, WET Systems actively work with our partners to integrate eco-technologies with other treatment systems (such as activated sludge, MLE, trickling filters, DAF, membranes and mechanical processes). Through careful and sympathetic design, the advantages of various technologies can be harnessed to provide logical and efficient outcomes.

This page provides an overview of the various constructed wetland technologies that WET Systems specialize in.

What are Constructed Wetlands?

A constructed treatment wetland is a water quality improvement system specifically designed to harness and optimise the contaminant degradation and transformation processes that occur in natural wetlands; only in a more engineered and efficient way. They are engineered systems consisting of wetland plants growing in a lined basin. The polluted water to be cleaned flows amongst the stems or roots of the plants and associated soil media or substrate (depending on the specific design).

Most pollutants are transformed into organic matter, inert sediments or harmless gases. The water receives treatment through a range of biogeochemical and physical mechanisms, including microbial degradation, sedimentation, filtration, adsorption, precipitation, oxidation, reduction and uptake by plants, algae and microoganisms growing within the system.

Many of the treatment processes occurring in constructed wetlands are fundamentally fueled by solar energy, via the process of photosynthesis. Plants and algae utilize the energy from the sun to grow, produce biomass and take up water and nutrients. CO2 from the atmosphere is converted into organic matter which subsequently provides food for bacteria and other microorganisms to carry out many of the useful and important pollutant transformation processes. The unique adaptations of wetland plants which enable them to grow and survive in waterlogged conditions also help to transfer oxygen into the root-zone which promotes certain desirable treatment processes, without the need for electromechanical aeration equipment.

Types of Constructed Wetlands

A broad range of different wetland technologies exist, each with their own strengths and weaknesses, suited to different applications. Some are suited to small applications, while others are better for

large-scale projects. Some provide conditions that favour aerobic processes, while others are more suited to anaerobic processes, or a mix of both conditions.

Designing a wastewater treatment system can be thought of in a similar way to building a car. We combine different components depending whether we want the car to go fast or have a lot of pulling power; go off-road or stick to the highway; transport 8 people or carry a 1 tonne load in the back. In a similar way, we select and couple together different types of wetland technologies to build the most appropriate treatment system for the task at hand.

The various constructed wetland designs can be classified into different groups based on the way water flows through the system and the type of vegetation they contain, as described in the article by Fonder and Headley on our Resources page.

An overview of the main types of wetland technology which WET Systems utilise is provided below.

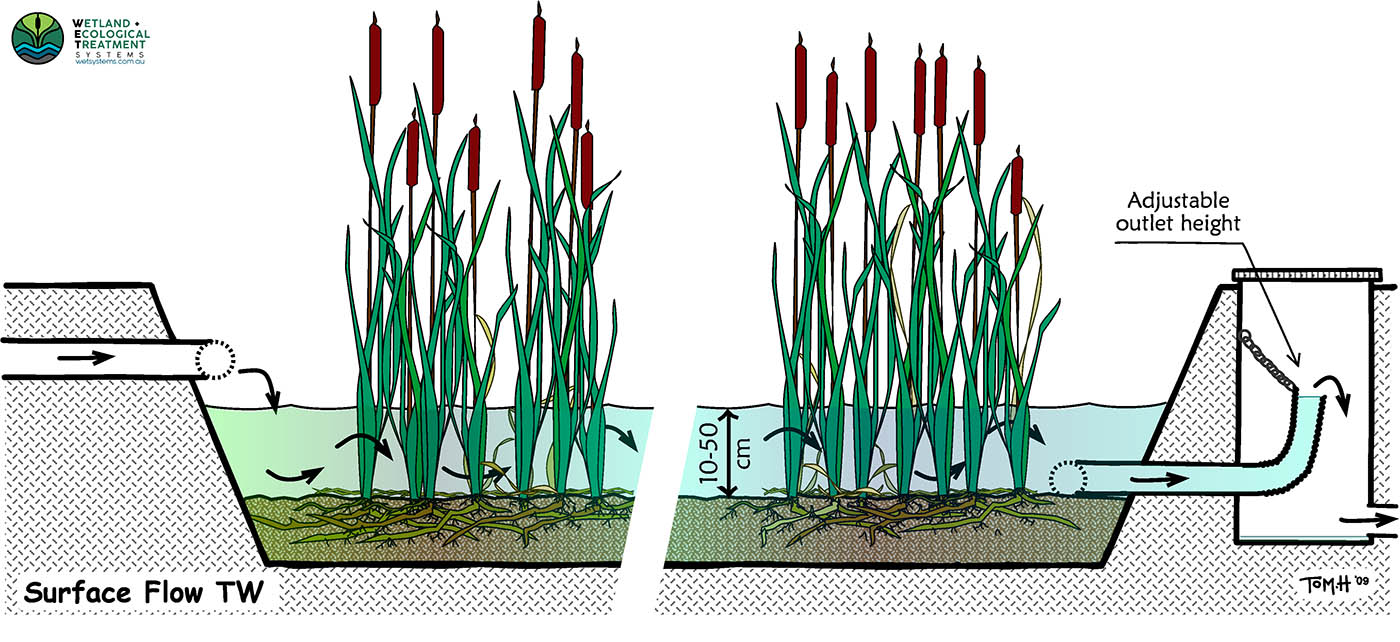

Surface Flow Wetlands (SFWs)

Surface Flow Wetlands, also known as Free-Water Surface (FWS) wetlands, are one of the oldest and most commonly applied types of constructed wetland. They resemble a natural marsh ecosystem, with emergent aquatic vegetation (macrophytes) rooted in a soil substrate. The water is usually shallow (0.1 – 0.6m), flowing predominantly over the surface of the soil, receiving treatment as it flows amongst the stems of the plants and the associated microbial biofilms (periphyton) which grow attached to the submersed plants, leaf litter and soil surfaces.

Compared to other wetland technologies, SFWs are especially suitable for large-scale applications because they can better accommodate high and variable flows and are typically less expensive to build (per unit area).

Common applications:

- tertiary polishing of sewage effluent

- urban stormwater

- agricultural drainage and runoff

- industrial wastewaters

- removal of nitrogen, phosphorus, organic matter, suspended solids and hydrocarbons

Advantages:

- Passive treatment without the need for electricity

- Relatively minimal hydraulic restrictions make them ideal for large or variable flows

- Use of topsoil from on-site and minimal need for imported sand and gravel media

- Provide good habitat and biodiversity values

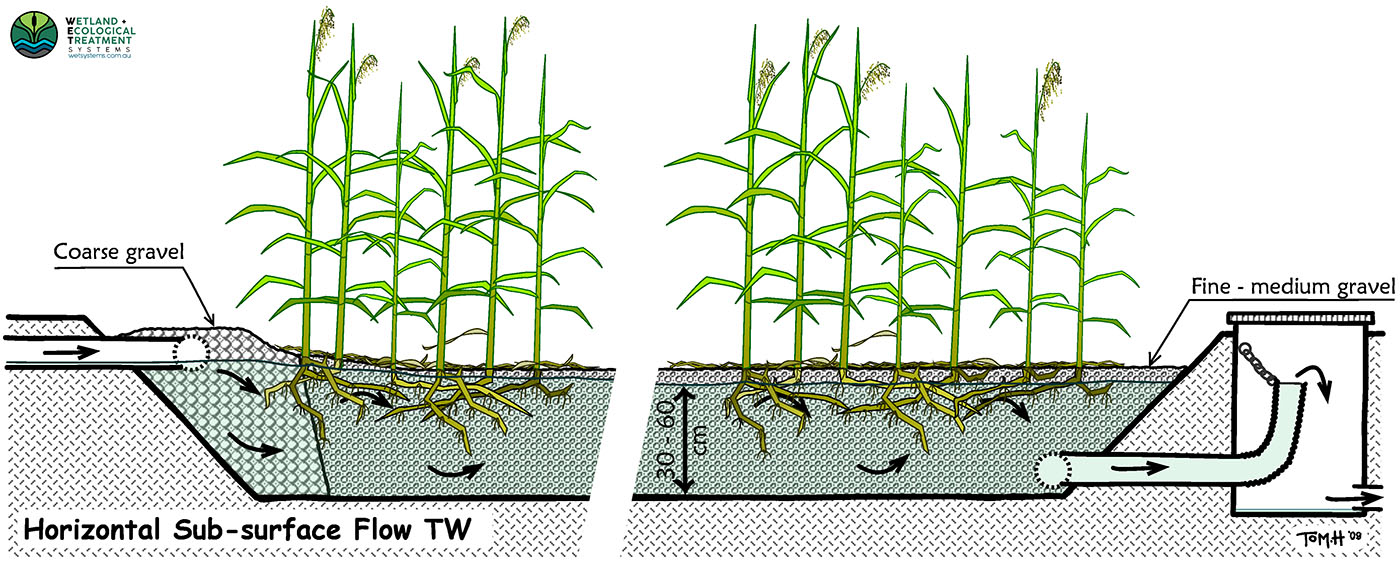

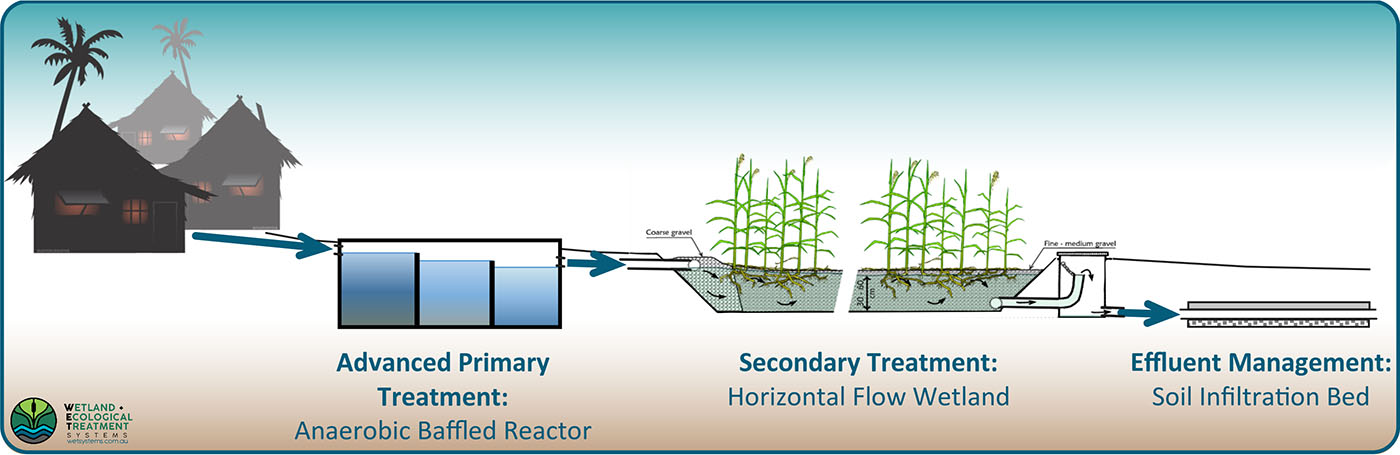

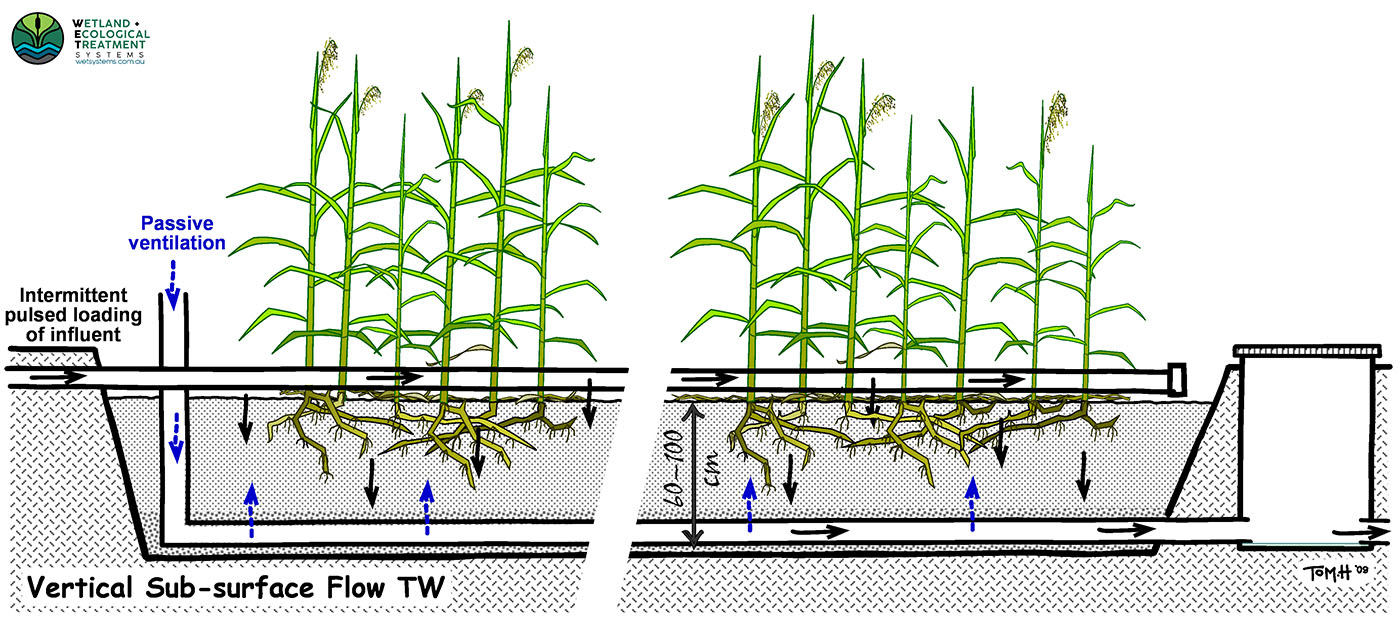

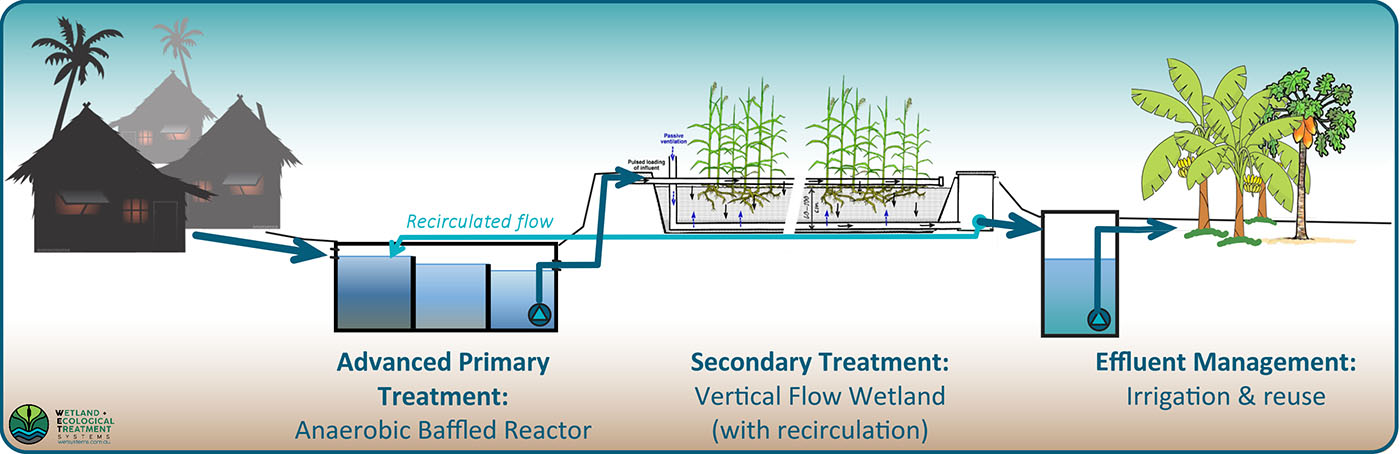

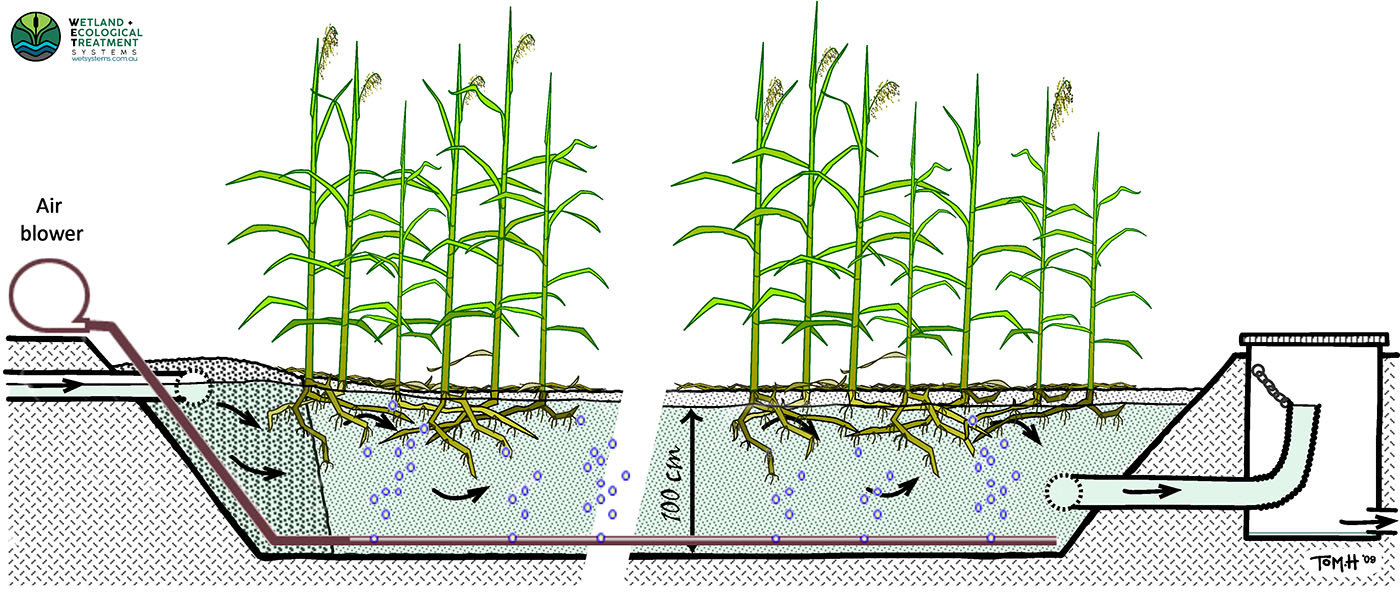

Subsurface Flow Wetlands

Subsurface Flow (SSF) Wetlands are a group of constructed wetland designs in which the water is passed through a lined basin containing porous media (e.g. sand or gravel), so that the upper surface of the system predominantly remains free of any exposed surface water. These systems are planted with emergent aquatic vegetation and the water passes through the root-zone of the plants. SSF Wetlands can be designed to operate with the water flow in either a horizontal or vertical (up or down) direction, depending on the treatment objectives and process requirements.

Subsurface Flow Wetlands tend to be more expensive to build per unit area than Surface Flow Wetlands due to the use of selected porous media which is typically purchased from off-site. However, in many applications SSF wetlands can provide treatment within a smaller footprint. SSF are highly suitable for small (e.g. household) to medium (e.g. village) sized applications wetlands, but tend to be less appropriate for very large applications due to the challenges in distributing and passing very large flows of water through the sand or gravel substrate.

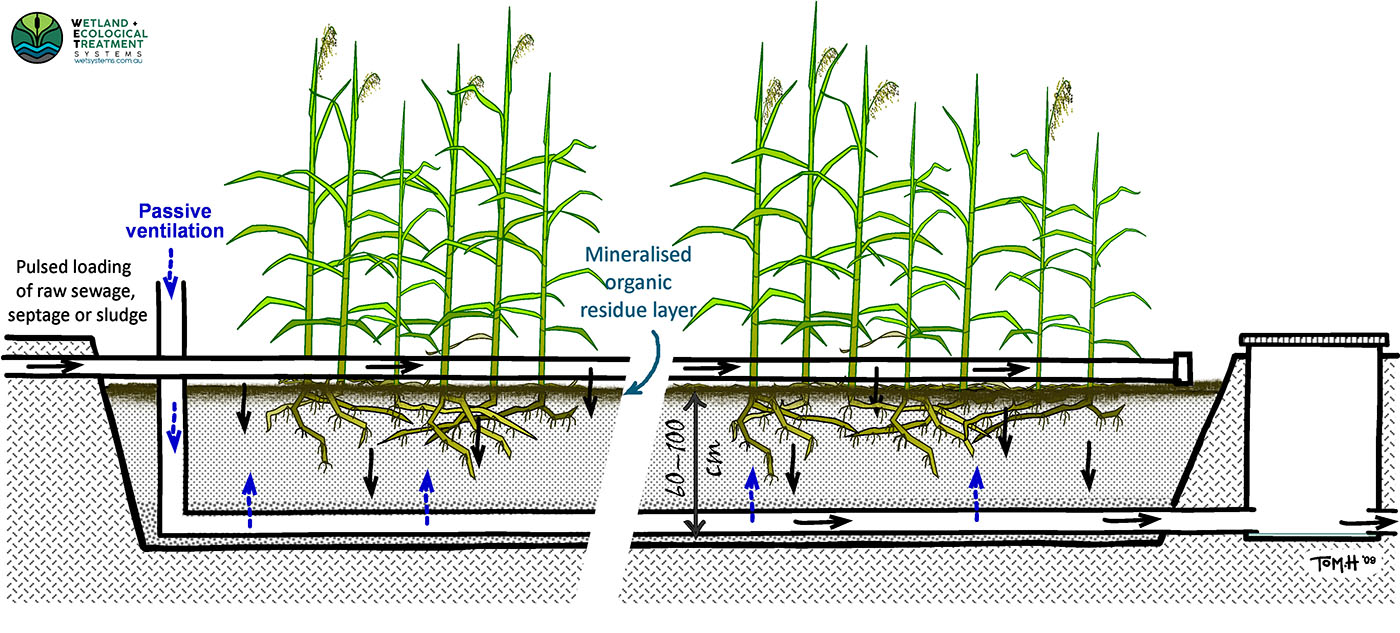

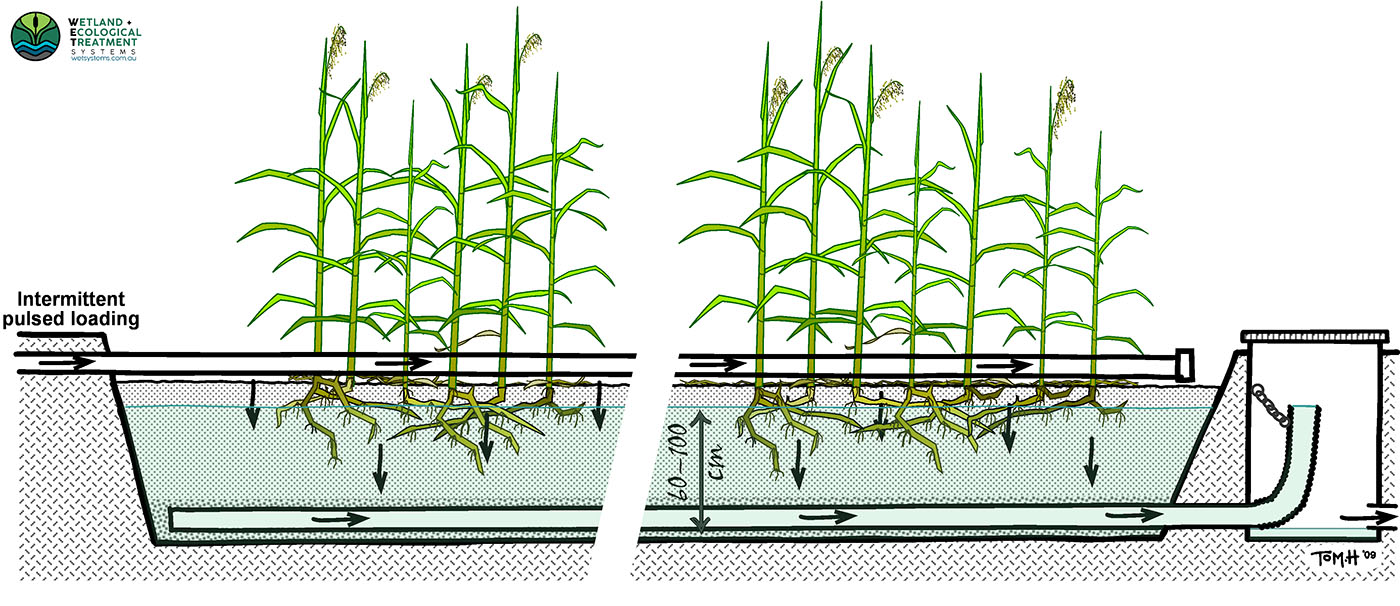

Sludge & Septage Treatment Wetlands

Sludge Treatment Wetlands (STWs), also known as Sludge Treatment Reed Beds (STRBs), are a specially adapted VFW variant. STWs take advantage of the high evapotranspiration rates and root-zone microbial activity of emergent wetland plants, to dewater and mineralize waste sludge from sewage treatment, septage and potable water treatment. They convert sludge into a high quality, stabilized biosolid product through energy efficient natural processes.

Several basins (typically 6 to 12) are used in parallel, with one bed being loaded (usually for 1 week at a time) while the remaining beds are rested (3 – 6 week rest period under Australian conditions). Sludge loading occurs for approximately 10 years before the stabilised, dewatered biosolids is removed (one basin per year) and land applied as a soil amendment.

Many large systems have been in operation for several decades since the emergence of the technology in Denmark during the 1980’s. This tried and proven, sustainable sludge management technology is now being introduced to Australasia, where the warmer climate conditions leads to enhanced performance and improved efficiency.

Common Applications:

- Waste (or Surplus) Activated Sludge

- Septage and other sludges

- Decentralised and municipal scale systems

Advantages:

- Decades of scientific study and design optimization in Europe (especially Denmark)

- Odours are avoided by maintaining aerobic conditions through the operational cycle of resting & loading

- Converts sludge into a stabilized, high quality biosolids resource with high dry matter content through the action of wetland plants and natural microorganisms

- Produces a filtrate low in organics and ammonia, reducing the oxygen demand when returned to the sewage treatment works

- Energy efficient

- No use of chemicals or mechanical equipment

- Reduces the carbon footprint of sewage management facilities

- A proven technology with a long case history of hundreds of large-scale systems operating for decades throughout Denmark, Germany, Sweden, France and elsewhere in Europe

Why Choose WET Systems?

AUSTRALIAN BASED & OWNED

We are an Australian business working throughout Australasia and further afield. Where possible, we support other local businesses and provide volunteer services to local groups in order to build a strong community.

BACKED BY EXPERIENCE

WET Systems has over 20 years of experience in the design and construction of constructed wetlands. We have worked across all states in Australia as well as the Middle East and Europe. We provide Australia’s most experienced constructed wetland design service coupled with excellent standards and honesty.

PARTNERING WITH CLIENTS

We work closely with our clients to create, design and implement treatment systems to meet their specific needs. We greatly value client input through all stages of the project and aim to grow strong, trusting relationships in order to create the best outcome.

Contact WET Systems

Contact WET Systems

Contact the wetland & ecological treatment system professionals to learn how we implement ecological-oriented waste water management solutions.